Initium I

Initium I

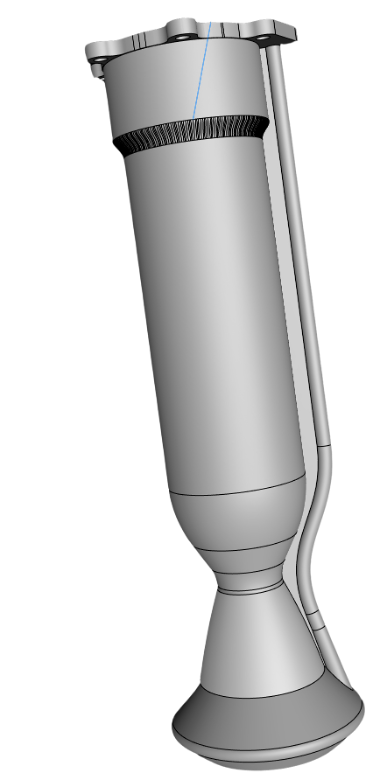

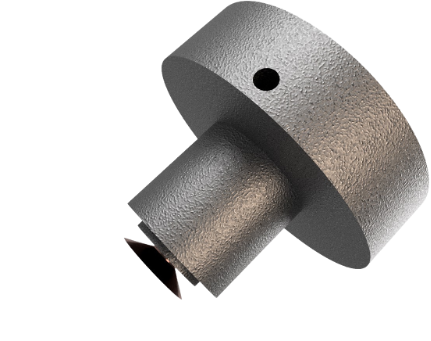

The Initium I is a liquid bi-propellant rocket designed to deliver payloads of up to 50 kg to Low Earth Orbit (LEO) with reliability, cost emciency, and environmental responsibility. Our rocket, which is loosely based on the A4/V2 missile, utilizes Hydrogen Peroxide (H₂O₂) as a non-cryogenic oxidizer that avoids any internal combustion, enhancing reliability and minimizing turnaround time to relaunch the same day. The Initium I rocket engine can be broken down into four key parts: the turbopumps, the injector, the catalyzer, and the nozzle.

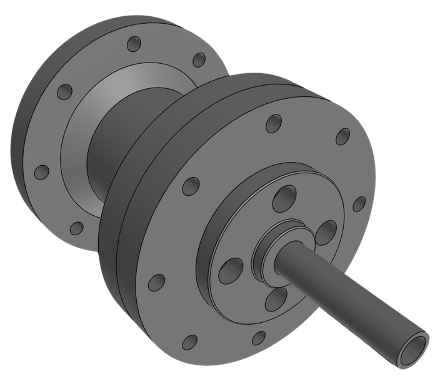

Our rocket’s innovative turbopumps are powered by the decomposition of H₂O₂ to drive a turbine without relying on any pre-burners or internal combustion. This drastically reduces internal heat stress within the engine, soot buildup, and maintenance requirements, providing a cheaper, more reliable, and environmentally friendly rocket system. The pumps deliver RP-1 (Refined Kerosene) and decomposed Hydrogen Peroxide to the combustion chamber.

The combustion chamber designed by Initium Aerospace is made from an alloy called AlSi10Mg, an extremely tough material able to withstand the extreme pressures of combustion. To prevent material degradation, we have also fitted the nozzle with regenerative and film cooling. For the regenerative cooling, RP-1 flows through various feed channels surrounding the outside of the combustion chamber to absorb heat from the walls. For the film cooling, some of the RP-1, after having passed through the cooling channels, is injected through small holes along the top of the combustion chamber walls.

This RP-1 then flows down the walls of the combustion chamber, acting as a barrier between the hot gases and the chamber walls. The RP-1 absorbs significant heat, powerfully regulating the thermal stress on the walls.

The Hydrogen Peroxide in the system is decomposed via a catalyzer specifically designed by Initium Aerospace. We have chosen a silver mesh monolith through which the HTP passes and decomposes. This decomposition releases high-temperature, high-pressure steam and oxygen, which we take advantage of as a clean and emcient power source for the turbopumps.

The Sheer Coaxial Injector is positioned on top of the nozzle, where the regenerative feed channels meet. It collects RP-1 from the regen cooling channels and decomposed H₂O₂ and injects them at extremely high pressures—5 MPa at the inlet and around 4 MPa in the combustion chamber. The oxidizer and fuel are injected into the chamber at a carefully calibrated oxidizer-to-fuel ratio, promoting a balanced and stable burn that maximizes thrust emciency.

The Initium I is currently in its design phase. We aim for it to become the ideal platform for future government contracts, delivering small satellite launches, space debris collection, and defense solutions more easily, faster, and at a more competitive price.

Launch Your Future with Initium Aerospace

London

At Initium Aerospace, we’re revolutionizing the future of space exploration with innovative engineering, sustainable designs, and unparalleled reliability.

Call Us : +447389810211

We are open from Monday to Friday

09:00 AM - 17.00 PM